orresponding to other steel grades:DAC SKD61 DH-31S 1.2344 W320

8407ESR is high purity and fine microstructure obtained by special steelmaking technology and strict quality control, which is better than the H13 quality of conventional refining. This is better for mechanical fatigue performance and thermal stress fatigue performance, such as die casting die, forging die and hot extrusion die. 8407ESR die hardness H13 increase 1~2 than usual without reducing toughness, can slow the occurrence of thermal cracking, it can make die life provide, performance more stable.

Chemical composition%

| C | Si | Mn | Cr | Mo | V | P | S | Cu | Factory Status |

| 0.32/0.45 | 0.80/1.20 | 0.20/0.50 | 4.75/5.50 | 1.30/1.50 | 0.80./1.20 | ≤0.030 | ≤0.030 | ≤0.030 |

Annealing HB ≤ 235 |

Purpose

Aluminum-magnesium alloy die casting die, hot extrusion die, plastic die, especially suitable for large or complex shape die.

Heat treatment

Soft annealing:

heated to 850℃ in a protective atmosphere, cooled to 650℃ at a cooling rate of 10℃/ h, then air cooled. to eliminate the residual stress after roughing, the die is heated to 650℃, and the furnace is cooled to 500℃ after 2 hours of heat preservation, and then air cooled.

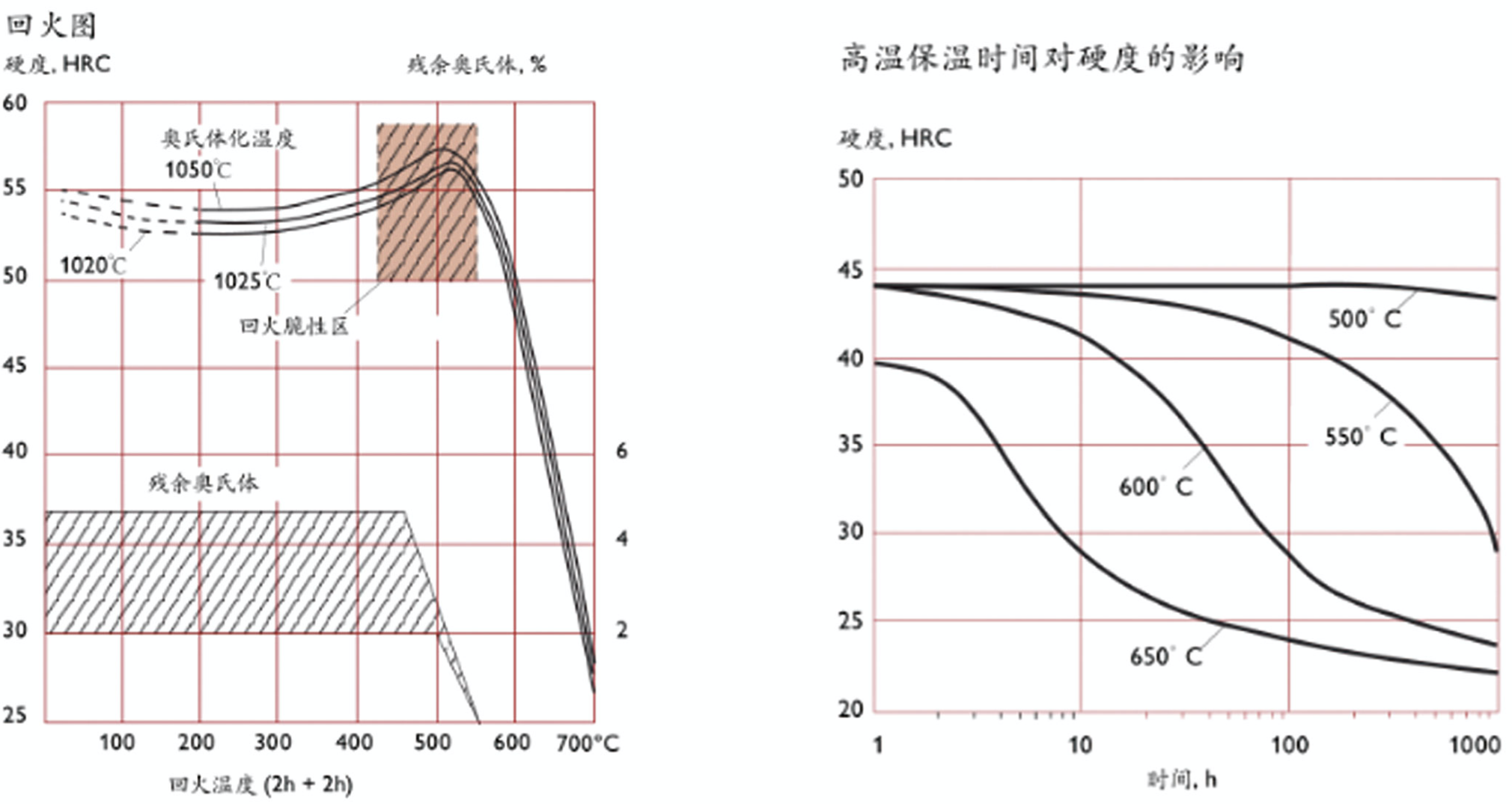

Tempering diagram

Surface nitriding

The surface after nitridation treatment has high hardness, good wear resistance and corrosion resistance, but its toughness is relatively poor. it is suggested that 480~520℃ plasma nitriding should be used, and the depth of the nitriding layer of die casting die should not exceed 0.1 mm, and the depth of nitriding of hot forging die should be 0.1~0.3 mm.

Electrosparking

After EDM, the surface of the die should be ground or polished to remove the "EDM white layer ", and then returned to the fire treatment at a temperature higher than the original tempering to eliminate the stress produced by EDM.Welding

The mold can be repaired by welding, before welding, the mold should be heated slowly and evenly to 325~375℃ preheating, if large area surface surfacing should be done in annealing state and need to be quenched and tempered again.

Hard chrome plating

After hard chrome plating, the mold must be tempered at 180℃ in time for 4 hours to avoid hydrogen embrittlement.

中文

中文 EN

EN